Minerals Processing Mining Centrifugal Industrial Sand Solids Water Rubber Ultra Chrome Alloy Slurry Pump

Rubber Slurry Pump Introduction: DeShi rubber slurry pump, the wearing parts are made of anti-abrasive and anti-corrosiv

Basic Info

| Model NO. | R150HS-E |

| Working Pressure | High Pressure Pump |

| Influent Type of Impeller | Single Suction Pump |

| Position of Pump Shaft | Horizontal Pump |

| Pump Casing Combined | Horizontal Split Pumps |

| Mounting Height | Suction Centrifugal |

| Impeller | Closed |

| Usage | Pump, Condensate Pump, Ash Pumps |

| Wet Parts | Natural Rubber |

| Drive Type | Electric Motor |

| Interchangeable | International |

| Colour | Requested |

| Transport Package | Wooden Packaging Box |

| Specification | 6 inch discharge |

| Trademark | DSP |

| Origin | Shijiazhuang, China |

| HS Code | 8413709990 |

| Production Capacity | 1800 Sets/Year |

Product Description

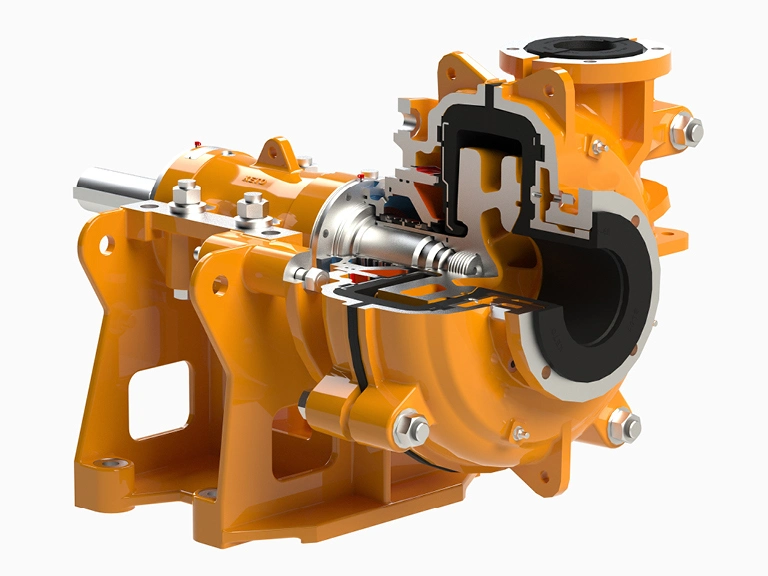

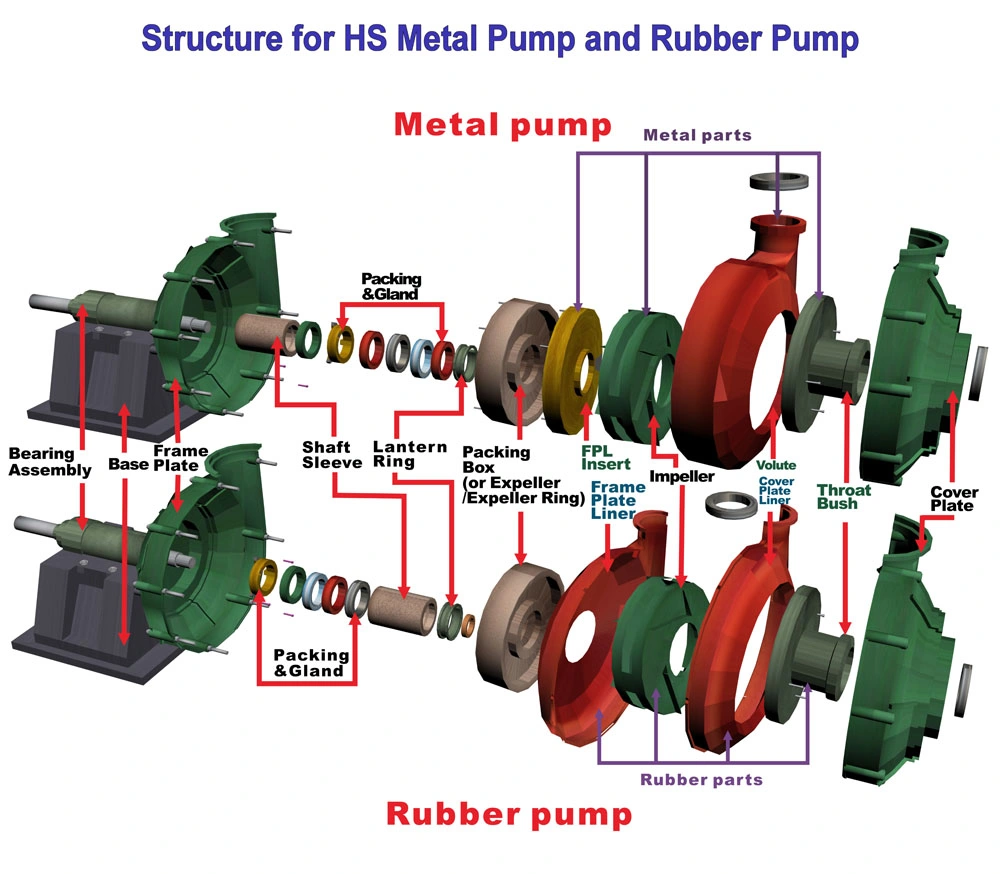

Rubber Slurry Pump Introduction:DeShi rubber slurry pump, the wearing parts are made of anti-abrasive and anti-corrosive natural rubber,

which can be perfectly interchangeable with the metal parts. Clients can choose different material parts

according to the slurry liquid conditions.

Rubber lined slurry pumps are more suitable in delivering high corrosive or abrasive slurries of small

particle size without hard or sharp edges.

Rubber wet parts can be replaced by the polyurethane parts.

Detailed Features:

1. Well designed for interchangeable wet parts with metal lined slurry pump.

2. Casing - Casing halves of cast or ductile iron with external reinforcing ribs contain the wear liners and provide

high operating pressure capabilities

3. Bearing assembly - A large diameter shaft with short overhang minimizes deflection and contributes to long

bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

4. Pump frame - A rigid, one-piece casting cradles the "cartridge" shaft and bearing assembly. A minimal

number of through bolts hold the pump casing to the frame. An easy means of external impeller adjustment

is provided in a convenient position below the bearing housing.

5. Impeller - Front and rear shrouds have pump-out vanes. This design reduces recirculation and seal

contamination, Elastomer impellers are made from rubber coated high tensile steel, Cast-in impeller threads

require no impeller insert or nuts.

6. Liners - Rubber elastomer liners are interchangeable with hard metal. The elastomer liners are bolted,

not bonded, to the outer casing. Elastomer seal rings back all liner joints.

7. Shaft seal - Packing seal,Centrifugal seal, and Mechanical seal.

8. Driving type - Flexible coupling,V-belt with pulleys,Gearbox,VFD,SCR control etc.

9. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

10. Easy to install and maintain in on-site application.

| Model | Max Power (Kw) | Inlet & Outlet size (inch) | Material for Wear Parts | Flow Rate (Q) | Head (H) meter | Speed (RPM) | Impeller Dia. (mm) | |

| m³/hr | l/s | |||||||

| 25HS-B | 15 | 1.5/1 | M | 12.6~28.8 | 3.5~8 | 6~68 | 1200~3800 | 152 |

| R | 10.8~25.2 | 3~7 | 7~52 | 1400~3400 | 152 | |||

| 40HS-B | 15 | 2/1.5 | M | 32.4~72 | 9~20 | 6~58 | 1200~3200 | 184 |

| R | 25.2~54 | 7~15 | 5.5~41 | 1000~2600 | 178 | |||

| 50HS-C | 30 | 3/2 | M | 39.6~86.4 | 11~24 | 12~64 | 1300~2700 | 214 |

| R | 36~75.6 | 10~21 | 13~46 | 1300~2300 | 213 | |||

| 75HS-C | 30 | 4/3 | M | 86.4~198 | 24~55 | 9~52 | 1000~2200 | 245 |

| R | 79.2~180 | 22~50 | 5~34.5 | 800~1800 | 245 | |||

| 100HS-D | 60 | 6/4 | M | 162~360 | 40~100 | 12~56 | 800~1550 | 365 |

| R | 144~324 | 40~90 | 12~45 | 800~1350 | 365 | |||

| 150HS-E | 120 | 8/6 | M | 360~828 | 100~230 | 10~61 | 500~1140 | 510 |

| R | 324~720 | 90~200 | 7~49 | 400~1000 | 510 | |||

| 200MS-E | 120 | 10/8 | M | 666~1440 | 185~400 | 14~60 | 600~1100 | 549 |

| 200HS-ST | 560 | 10/8 | M | 612~1368 | 170~380 | 11~61 | 400~850 | 686 |

| R | 540~1188 | 150~330 | 12~50 | 400~750 | 686 | |||

| 250HS-ST | 560 | 12/10 | M | 936~1980 | 260~550 | 7~68 | 300~800 | 762 |

| R | 720~1620 | 200~450 | 7~45 | 300~650 | 762 | |||

| 300HS-TU | 560 | 14/12 | M | 1260~2772 | 350~770 | 13~63 | 300~600 | 965 |

| R | 1152~2520 | 320~700 | 13~44 | 300~500 | 965 | |||

| 350HS-TU | 1200 | 16/14 | M | 1368~3060 | 380~850 | 11~63 | 250~550 | 1067 |

| 450HS-TU | 1200 | 20/18 | M | 2520~5400 | 700~1500 | 13~57 | 200~400 | 1370 |

| 25HHS-C | 30 | 1.5/1 | M | 16.2~34.2 | 4.5~9.5 | 25~92 | 1400~2200 | 330 |

| 50HHS-D | 60 | 3/2 | M | 68.4~136.8 | 19~38 | 25~87 | 850~1400 | 457 |

| 75HHS-E | 120 | 4/3 | M | 126~252 | 35~70 | 12~97 | 600~1400 | 508 |

| 100HHS-E | 120 | 6/4 | M | 324~720 | 90~200 | 30~118 | 600~1000 | 711 |

| 150HHS-S | 560 | 8/6 | M | 468-1008 | 130~280 | 20~94 | 500~1000 | 711 |

"M" = metal, ultra chromium alloy;

"R" = anti-abrasive rubber

Welcome to contact us any time for details.

Your inquiry will get our prompt attention and response !